Lok-Ring Joint Pipe

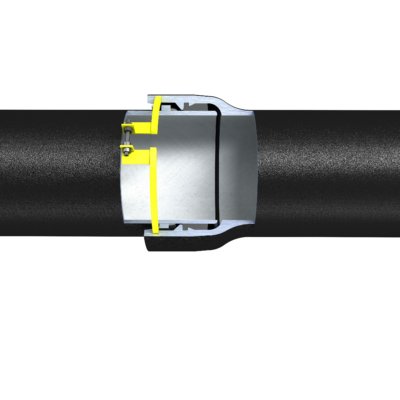

The AMERICAN Lok-Ring joint is a restrained joint that utilizes the sealing features of the time-proven AMERICAN Fastite joint. It is an essentially boltless, flexible restrained connection that provides an easily assembled positive restraint against endwise separation due to thrust resulting from internal pressure or external forces. Only a minimal amount of time is required to complete the Lok-Ring assembly, or disassembly if necessary.

The patented1 AMERICAN Lok-Ring joint is designed for working pressures up to 250 psi for sizes 60" through 64". If higher pressure ratings are needed, contact AMERICAN. The Lok-Ring joint can be used with any lesser pressure class of ductile iron pipe, with the maximum operating pressure rating of the joint limited in such cases to that of the pipe. An alloy steel welded-on retainer ring and a split lok-ring, assembled behind the retainer ring, provide the means of restraint. The split lok-ring is held “snug” and constricted against the pipe OD for assembly of the AMERICAN Fastite portion of the joint. After the plain end of the pipe is assembled into the Lok-Ring bell, the lok-ring is released, permitting it to expand. The lok-ring is thus securely positioned behind the welded-on retainer ring and in the socket locking groove on the ID of the Lok-Ring bell. This locks the joint.

The lok-ring, welded retainer ring and all parts of the closure-spreader mechanism are all constructed of corrosion-resistant, high-strength, low-alloy (HSLA) steel. This is the same type of steel specified for bolting material per ANSI/AWWA C111/A21.11, and it has been used successfully in several AMERICAN restrained joint constructions for approximately 40 years. The weld is aluminum bronze, and both the weld and ring are cathodic to – and thus protected by – the greater mass of the ductile iron pipe. Welding is performed using welders qualified to produce high-quality, dependable welds.

The AMERICAN Lok-Ring joint utilizes standard Fastite gaskets and lubricant, and, like the Fastite joint, the Lok-Ring joint is designed to permit deflection in order to facilitate installation and accommodate settlement. It is noted that rotation of the lok-ring under great loads helps to distribute the forces substantially around and between the bell and spigot members.

AMERICAN Lok-Ring Pipe is ductile iron, grade 60-42-10, manufactured and tested in accordance with AWWA C151. It is normally furnished standard asphaltic-coated outside and cement-lined inside in accordance with AWWA C104. When specified, other special linings can be furnished. Fittings are available in both bell-bell and bell-plain end configurations for installation versatility and economy.