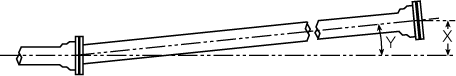

Deflection and Offset

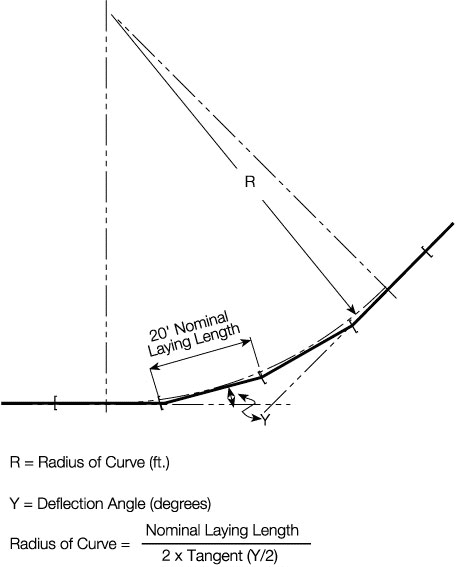

The liberal allowable deflection in the Fastite joint facilitates the installation of pipelines that include sweeping horizontal or vertical curves without the use of fittings.

For optimum assembly, the joints should be assembled with the pipe in reasonably straight alignment. After joint assembly, the pipe may be deflected up to the maximum shown. Offset distances and radii are based on nominal lengths shown.

| Size (in.) | Nominal Laying Length (ft.) |

Standard Bell | ||

|---|---|---|---|---|

| X Offset per Nominal Length (in.) |

Y Deflection Angle |

Radius of Curve1 (ft.) |

||

| 4 | 20 | 21 | 5° | 206 |

| 6 | 20 | 21 | 5° | 230 |

| 8 | 20 | 21 | 5° | 230 |

| 10 | 20 | 21 | 5° | 230 |

| 12 | 20 | 21 | 5° | 230 |

| 14 | 20 | 21 | 5° | 230 |

| 16 | 20 | 21 | 5° | 230 |

| 18 | 20 | 21 | 5° | 230 |

| 20 | 20 | 21 | 5° | 230 |

| 24 | 20 | 21 | 5° | 230 |

| 30 | 20 | 21 | 5° | 230 |

| 36 | 20 | 17 | 4° | 285 |

| 42 | 20 | 12 | 3° | 380 |

| 48 | 20 | 12 | 3° | 380 |

| 54 | 20 | 12 | 3° | 380 |

| 60 | 20 | 12 | 3° | 380 |

| 64 | 20 | 12 | 3° | 380 |

| Size (in.) | Nominal Laying Length (ft.) |

Special Deflection Bell | ||

|---|---|---|---|---|

| X Offset per Nominal Length (in.) |

Y Deflection Angle |

Radius of Curve2 (ft.) |

||

| 36 | 20 | 21 | 5° | 230 |

| 42 | 20 | 21 | 5° | 230 |

| 48 | 20 | 17 | 4° | 285 |

| 54 | 20 | 17 | 4° | 285 |

| 60 | 20 | 17 | 4° | 285 |

| 64 | 20 | 17 | 4° | 285 |

1 Special deflection bells must be specifically ordered and will be marked with white bell face for easy identification. For easiest assembly, the joints should be assembled with the pipe in reasonably straight alignment. After joint assembly, the pipe may be deflected up to the maximum shown above. Offset distances are based on 20’ lengths.

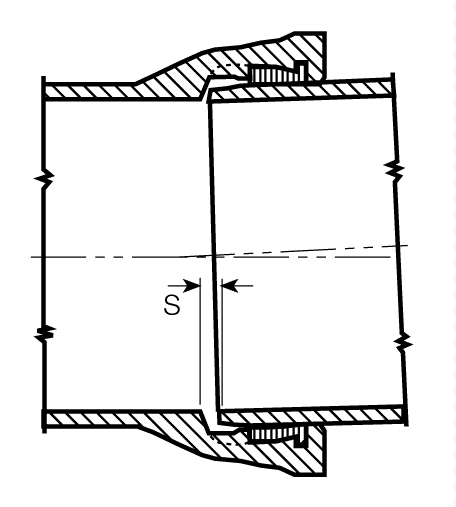

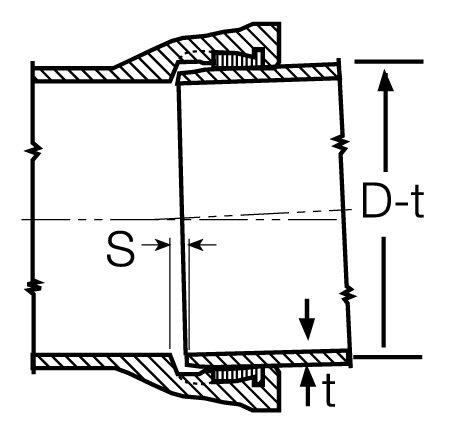

Maximum Allowable Separation

Maximum allowable separation in standard bell pipe is approximately equal to the median pipe diameter in inches times the sine of the deflection angle. This is provided for information only and should not be used to determine precise joint deflection.

| Size (in.) | S Separation (in.) |

|---|---|

| 4 | 3/8 |

| 6 | 9/16 |

| 8 | 3/4 |

| 10 | 15/16 |

| 12 | 1 1/8 |

| 14 | 1 5/16 |

| 16 | 1 1/2 |

| 18 | 1 5/8 |

| 20 | 1 7/8 |

| 24 | 2 1/4 |

| 30 | 2 3/4 |

| 36 | 2 5/8 |

| 42 | 2 1/4 |

| 48 | 2 1/2 |

| 54 | 2 7/8 |

| 60 | 3 1/8 |

| 64 | 3 3/8 |